As in previous Ryder Cups, all players had to be members of the European Tour to be eligible to play for Europe. Membership criteria for the European Tour were reduced from five tournaments to four (outside the majors and WGCs) for the 2018 season.

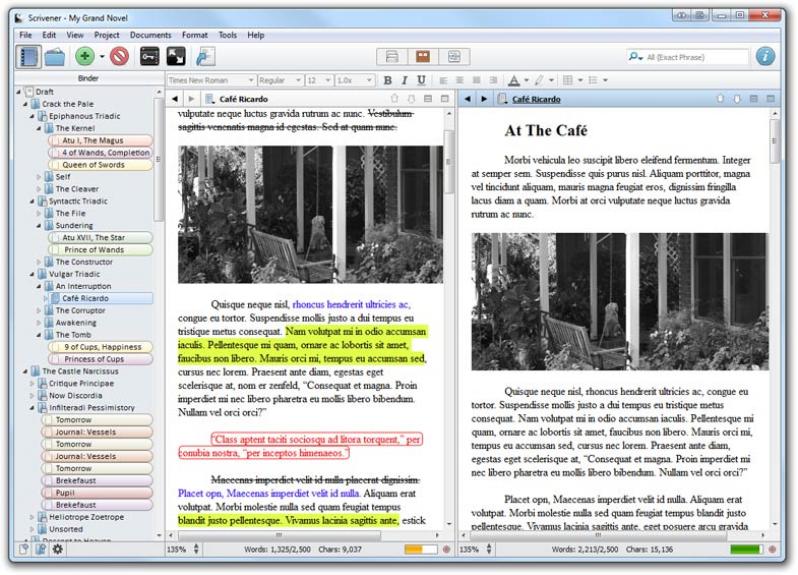

SCRIVENER 2.8.1.2 DOWNLOAD SERIES

No World points were earned from tournaments staged opposite Rolex Series tournaments in both 20. Points earned from the date of the 2018 BMW PGA Championship onwards, were multiplied by 1.5.

In addition, the application of CS/GO nanocomposite could improve the stability of this coating and able to stop the dripping tendency even after 10 laundering cycles as well.The Ryder Cup is a match play event, with each match worth one point. Furthermore, the as-prepared hybrid coatings imparted better hydrophilicity as a 2BLs deposition along with pad-dry-cure treatment by CS/GO could boost up the hydrophilicity of the treated fabrics further compared to the only 2BLs deposited fabric sample. Moreover, a considerable improvement in thermal stability and char yield% were also realized in the thermogravimetric analysis (TGA) test. A 2BLs deposited hybrid coating (i.e., PA6.6-g-AA-2BL-CS/GO) could decrease the peak heat release rate (pHRR) by 47.1 % whereas a maximum reduction of pHRR by about 56 % was achieved for 5BLs deposition. Obtained results indicated that these hybrid coatings could significantly improve the flame retardancy as the limiting oxygen index (LOI) value reached up to 25 % from 18.5 % and could completely stop the melt dripping where the fabric sample with two bilayers deposition and simultaneously treated with CS/GO nano-composite (PA6.6-g-AA-2BL-CS/GO) achieved a V-1 rating. The layer by layer (LBL) deposition of chitosan/melamine/urea (CS/ME/UREA) and phytic acid (PA) onto the acrylic acid (AA) grafted Polyamide 6.6 (PA6.6) fabrics including a pad-dry-cure treatment with chitosan/gra-phene oxide (CS/GO) nanocomposites were considered to improve the hydrophilicity and durable flame re-tardancy. The treated fabrics showed good water repellency and excellent flame retardant properties asdetermined by the standard test methods. Cotton was functionalized withepoxy and carboxyl via grafting cotton with nano-emulsion consisted of mixture of glycidyl methacrylate(GMA) and acrylic acid (AA), and then treated for functional finishing through conventional pad-dry-curemethod. Theparticle size was investigated using Transition Electron Microscope (TEM) and the chemical structurewas investigated using FT-IR analysis and other analytical techniques. In This con-text, new preparation techniques were used to prepare both aminated silica and ZnO nano-particles. Complex coating with amino-functionalized silica nano-particles onepoxy-functionalized cotton accompanied with ZnO nano-particles coating are carried out. A simpleand facile method for fabricating the cotton fabric with superhydrophobicity and flame retardancyis described in the present work. TEnvironmental concerns related to fluorinated and organophosphorus compounds led to a consider-ation of the methods for imparting flame retardancy and water/oil repellency to textiles.

0 kommentar(er)

0 kommentar(er)